EWIE Company is a global leader in commodity management services spanning cutting tools, abrasives, special tools and industrial supplies with over 30 years of experience.

Our specialty is in total tool management.

At EWIE, we strive to lead in implementation and management of solutions focused on supply chain optimization for metalworking and industrial supply commodities.

The objective of these solutions is to reduce customers “Total Cost” while increasing customer satisfaction.

Our team of procurement specialists, analysts, engineers and information technology personnel has a passion for continuous improvement.

EWIE currently manages over 70,000 parts comprising millions of dollars of inventory at over 94 contracts globally.

Our unique approach of maintaining manufacturer neutrality through managed competition and focus on best-in-class solutions creates an environment of innovations where good ideas become embedded in the process. This approach has delivered over $100 million dollars in engineered cost savings for our customers.

Leadership

|

Dilip Mullick, Co-Founder (1950-2017) | |

| Manoj K. Sachdeva, Chairman/CEO/President/Co-Founder |

||

|

Jay Mullick, Co-President | |

|

Scott Burk, Co-President | |

| Amit Sachdeva, Vice President | ||

| Joey Mullick, Vice President | ||

| Rick Mullick, Vice President | ||

| Alexander Broetz, Vice President of Europe and Asia | ||

| Louis Green, Global Director of Diversity Strategy, EWIE Group | ||

| Chuck Byrnes, VP of Global Strategy, EWIE Group | ||

| Brian Peters, C.O.O. | ||

| Tom Connelly, Director of Sales | ||

| Rick Simmons, Director of Finance | ||

| Virginia, HR Manager, EWIE Group | ||

| Donna Rivard, Director of Finance & Operations(Canada) |

||

| Subin Babu, Director of Technology | ||

| Jez Quigg, Director of Finance & Administration, EWIE Europe | ||

| David Evans, Director of Sales, EWIE Europe | ||

| Ignacio Pastrana, Country Manager, EWIE De Mexico |

|

|||||||||||||

|

|||||||||||||

|

|||||||||||||

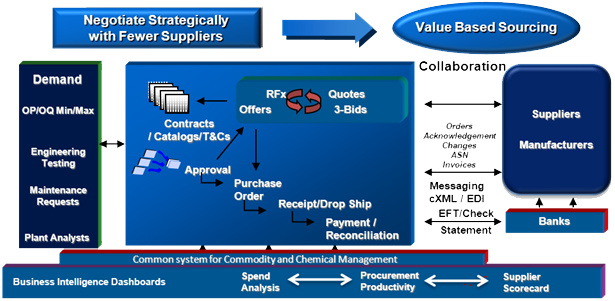

| Our full service value chain management aims at reducing procurement, inventory and process costs across the entire supply chain. Instead of managing hundreds of suppliers and resulting invoices, our customers get one invoice from EWIE. EWIE takes the responsibility of managing the complete life cycle of all the industrial supply products in a manner that reduces Total Cost of Ownership. | |||||||||||||

|

|||||||||||||

|

|||||||||||||

| Our corporate concerns promote stewardship for continual process improvement, to lessen environmental impact and strengthen our commitment to a diverse supplier base to empower people in our communities where we live and work. | |||||||||||||